❗Own experience ❗The ERP Disaster: A One-Person Company’s Costly Mistake

A small medical supplies distributor in Belgium—one founder, no employees—decided to go all in on an ERP system. The goal? Automate orders, track inventory, and simplify accounting.

What happened instead? A total mess.

❌ Where It Went Wrong:

🔹 No Real Planning – The founder assumed the ERP would “just work.” No one mapped out how supplier pricing, customer orders, or inventory tracking should flow. The system didn’t match the business.

🔹 No Testing, No Training – Instead of running test orders, they launched it blind. The first real order? Wrong pricing, missing stock locations, total confusion.

🔹 Focusing on the Wrong Things – The founder spent more time tweaking report layouts and button positions than making sure orders processed correctly.

🔹 Trying to Use ERP Like Excel – They wanted strict processes and full flexibility. But an ERP isn’t a spreadsheet—you can’t make up rules on the fly.

The Result?

The system went live, but nothing worked. Orders got delayed, financials didn’t add up, and instead of making life easier, it just created more headaches.

Lesson learned? ERP isn’t magic. You need proper setup, testing, and a real plan. Otherwise, it’s just an expensive disaster.

How to Get Your ERP Project Right (and Avoid a Costly Disaster!)

🚀 Implementing an ERP system can transform your business—but only if you do it right. Too many companies rush in, thinking software alone will fix everything. The truth? An ERP is only as good as the planning behind it.

If you want to avoid delays, confusion, and wasted money, follow these five key steps to get your ERP project right.

1️⃣ Start with a Plan: Know What You Want

🔹 Identify the problems with your current system. Are orders delayed? Is inventory tracking unreliable? Figure out what’s broken first.

🔹 Define your goals. Choose 3-4 key areas to improve, like:

✅ Faster order processing

✅ Fewer stock errors

✅ More accurate financial reports

🔹 Set measurable KPIs. If you don’t measure where you are now, you won’t know if the ERP is actually helping.

🔹 Stick to the plan. Don’t add last-minute features—keep the scope focused.

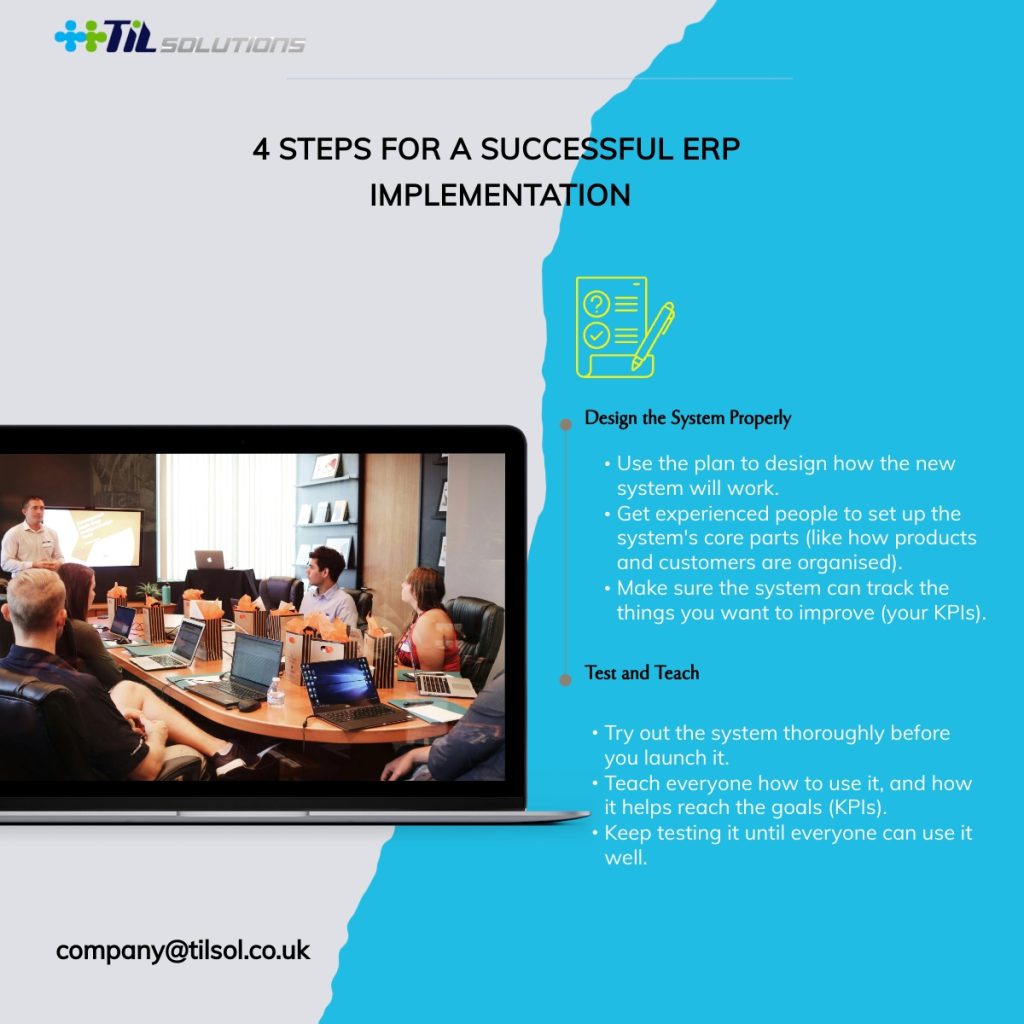

2️⃣ Design the System Properly

🔹 Use your plan as the foundation. Structure your ERP around what your business actually needs.

🔹 Get experienced setup experts. The way you organize products, customers, and suppliers matters. If done wrong, it’ll cause chaos later.

🔹 Make sure your system tracks your KPIs. The whole point is to improve key areas—make sure your ERP can measure them!

3️⃣ Put the Right People in Charge

🔹 Appoint a strong project leader. Someone needs to own this project and have the time to manage it properly.

🔹 Involve leadership. If top management isn’t engaged, the project will stall.

🔹 Make sure everyone understands the goals. ERP success isn’t just about IT—it’s about the whole business.

4️⃣ Test, Test, and Train

🔹 Run real-world tests before launch. Find and fix problems before they go live.

🔹 Train employees properly. If people don’t know how to use the system, it won’t matter how good it is.

🔹 Keep testing until the process is smooth. A rushed launch leads to mistakes, frustration, and expensive fixes.

5️⃣ Support Change & Keep Improving

🔹 This is more than just software—it’s a workflow shift. Help employees transition smoothly.

🔹 Keep tracking your KPIs after launch. Is the ERP actually improving your business? If not, adjust and refine.

🔹 Optimize as you go. No ERP is perfect from day one. Use real data to make continuous improvements.

🚀 Final Thought: ERP Success Comes from Smart Execution

A well-planned ERP saves time, improves efficiency, and boosts business growth. A poorly planned one? It creates confusion, delays, and wasted money.

💡 Have you ever been part of an ERP project—good or bad? Share your experiences in the comments!

📢 Need help getting your ERP project on track? Contact us today for expert guidance.